The modern vape cartridge has become a sophisticated engineered product rather than a simple oil container. As consumer expectations rise, brands try to deliver smoother vapor, stronger flavor, and consistent performance across a wide range of oil formulas. Because of these demands, engineers have shifted their focus toward precision-controlled cartridges built on scientific principles rather than experimentation. While flavor profiles and hardware aesthetics influence market trends, the true performance of a cartridge depends on three core variables: voltage, coil design, and oil viscosity.

This article examines these variables from a third-party technical perspective and explains how they interact to define a custom vape cartridge. At the same time, it discusses how RIMYI’s PCB and engineering solutions support the development of high-performance custom cartridges for brands that rely on consistency and reliability. By exploring these engineering details, the article highlights how scientific design transforms a simple vape cartridge into a controlled vaporization system.

1. Voltage: The Driver of Heating Precision

Voltage plays a central role in custom cartridge vape design because it directly influences heat generation. When engineers define the required performance level for a cartridge, they begin by examining the interaction between the power source and the heating element. Although many cartridges share a similar structure, the voltage range determines how fast the coil heats and how stable the vaporization process becomes.

Although some users believe higher voltage always delivers stronger vapor, the engineering perspective tells a different story. When the voltage rises too quickly, the oil may overheat and break down. Furthermore, high voltage can darken the oil, damage flavor compounds, and shorten coil life. Therefore, engineers often design regulated voltage ranges around the oil’s viscosity and the coil’s resistance. This approach ensures better control of the vapor temperature.

At the PCB level, smart regulation circuits now allow precise voltage delivery. Using RIMYI’s vape PCB solutions, device designers can integrate real-time power adjustment, allowing the cartridge to maintain consistent heat even as battery levels change. This improves vapor stability and reduces the common issue of weak hits caused by low battery output. As the market moves toward intelligent hardware, voltage regulation becomes a defining marker of advanced custom cartridge vape design.

2. Coil Structure: The Engine Behind Vapor Quality

2. Coil Structure: The Engine Behind Vapor Quality

Although voltage determines energy flow, the coil converts that energy into heat. Engineers focus heavily on coil structure because it governs flavor clarity, heating efficiency, and oil compatibility. The material, surface area, resistance level, and wicking geometry all shape how the coil performs during each puff.

Traditional coils used basic Kanthal wire, but today’s custom cartridge vape designs rely on ceramic heating cores or mesh-style structures. These advanced coils offer better heat distribution, improved oil absorption, and longer durability. Ceramic structures, in particular, enable stable heating because the porous matrix distributes oil evenly, preventing hotspots that degrade the oil.

Coil resistance also plays a key engineering role. Lower resistance allows faster heating, but it may demand tighter voltage control. Higher resistance slows heat generation, but it offers better protection for delicate oil formulas. When engineers combine resistance values with voltage profiles, they create a balanced heating curve tailored to specific oils.

Furthermore, the PCB inside a battery or integrated device communicates with the coil through current sensors. These sensors detect actual resistance changes during use. This data helps prevent overheating and improves consistency. RIMYI designs PCBs with these measurement features to help brands develop adaptive coil-matching systems, which adjust power automatically when oil conditions change during the vape session.

In summary, coil design acts as the physical engine behind vapor quality, while the PCB manages its behavior like a control computer.

3. Oil Viscosity: The Variable That Defines Hardware Requirements

Oil viscosity has one of the strongest influences on custom vape cartridge design. Because extract formulas vary widely—from thin terpene blends to extremely thick distillates—engineers must design cartridges that service specific oil characteristics rather than generic performance levels.

High-viscosity oils require strong wicking structures, wider heating surfaces, and careful temperature control to avoid burning the oil. Thin oils, however, need tighter seals, fine wicking channels, and lower heat intensity to prevent flooding. When engineers define coil geometry or voltage limits, they always consider oil viscosity first.

Therefore, the most successful custom cartridge vape designs begin with oil analysis. Engineers test flow behavior across extended temperature ranges to determine the ideal operating window. Because viscosity shifts as temperature changes, the heating system must remain stable throughout the session. This is where the PCB’s power-control functions become valuable.

Modern RIMYI PCB solutions integrate:

-

real-time temperature sensing,

-

intelligent power algorithms, and

-

stable output regulation

These systems compensate for viscosity fluctuations, ensuring consistent vapor even when oil thickness changes during long storage periods or cold conditions.

By combining coil material, wick structure, and voltage curves with oil viscosity, engineers create a cartridge that operates like a specialized vaporization tool rather than a universal device.

4. Interactions Between Voltage, Coil, and Oil Viscosity

Although each factor—voltage, coil structure, and oil viscosity—plays a distinct role, the true engineering challenge lies in balancing them. Engineers must treat the cartridge as a closed system where each variable influences the others.

For example:

-

High viscosity demands lower voltage and larger coil surfaces.

-

Thin oils require low heat and narrow wick paths.

-

Ceramic coils need a stable voltage to avoid micro-cracks.

-

Mesh coils can handle higher wattage but require controlled airflow.

-

Delicate terpene blends require gentle heating curves to retain flavor.

-

High-purity distillates need higher heat but stable temperature control.

RIMYI’s PCB solutions help manage these interactions by creating reliable power profiles for each oil type. The system collects feedback from sensors and adjusts output continuously, ensuring that the coil matches the oil’s behavior. This closed-loop design solves many common problems with custom cartridges, such as clogging, oil oxidation, coil burnout, and flavor instability.

As designers integrate deeper intelligence into cartridges, balancing these three engineering variables becomes a foundation for competitive product differentiation.

5. PCB Intelligence: The Hidden Layer in Custom Cartridge Design

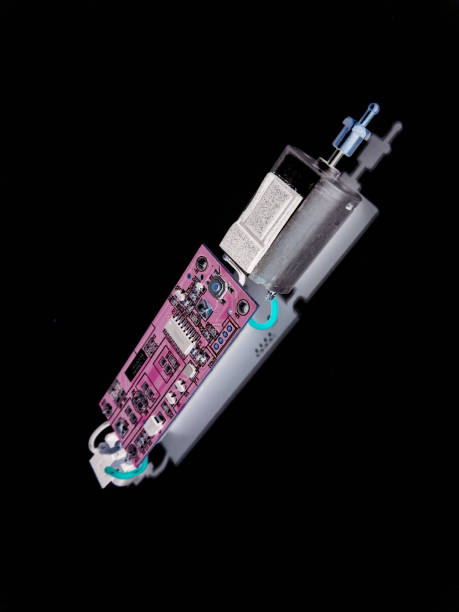

Although many users focus on the cartridge’s visible hardware, the internal PCB inside the battery or disposable system plays a crucial role in performance. In custom cartridge vape design, the PCB acts as the device’s operating system. Without precise power control, even the best coil and oil pairing cannot maintain consistency.

A modern vape PCB includes:

-

power management ICs,

-

microcontroller units,

-

current and voltage sensors,

-

temperature sensors,

-

protection circuits, and

-

firmware algorithms.

This intelligent control system ensures that the heating process stays within the oil’s optimal range. Because each oil profile demands different heating parameters, RIMYI’s PCB solutions allow customization at the firmware level, enabling brands to match specific coils with compatible voltage curves.

Therefore, the industry is moving toward a new era where hardware and PCB systems form a unified design ecosystem rather than separate components.

6. Engineering Testing: Validating a Custom Cartridge

6. Engineering Testing: Validating a Custom Cartridge

Custom cartridge vape design requires detailed testing to ensure that the product operates correctly in real-world use. Engineers conduct:

-

heat distribution analysis,

-

airflow modeling,

-

viscosity behavior tracking,

-

long-duration burn tests,

-

clogging simulations, and

-

voltage stability tests.

During these tests, RIMYI’s sensor-enabled PCB modules capture data and generate performance profiles. This data helps engineers identify inconsistencies or refine the coil geometry and voltage settings. Because each oil behaves differently, test loops often require dozens of iterations before engineers reach the final design.

This process reveals why successful custom cartridges rely on engineering discipline rather than visual trends or generic hardware structures.

Conclusion: Engineering Defines the Future of Custom Cartridge Vape Design

As the vape industry matures, performance expectations continue to rise. Brands understand that successful cartridges depend on scientific design, not generic hardware. Voltage, coil structure, and oil viscosity form the foundation of engineering decisions. However, their true power emerges when they work together within a controlled system.

RIMYI’s PCB solutions serve as the intelligence layer that unifies these variables through precise power management and real-time sensing. This integration allows brands to design cartridges that deliver consistent vapor, stable temperature control, and reliable performance across various oil formulas.

Therefore, the future of custom cartridge vape design will depend on how effectively engineers can optimize the interaction between electrical regulation, heating structure, and fluid-dynamic behavior. By aligning these elements with advanced PCB control systems, manufacturers can deliver refined experiences that match consumer expectations and support long-term hardware evolution.