Amidst increasingly stringent global e-cigarette regulations and a continuously reshaping market environment, Chinese manufacturing is undergoing a profound transformation. This article deeply analyzes the advantages and challenges faced by Chinese e-cigarette OEM enterprises, proposing a transition path from “OEM manufacturing” to “compliance standard export + brand co-creation,” offering strategic-level insights for industry development.

01 The Glory and Myth of the Manufacturing Powerhouse

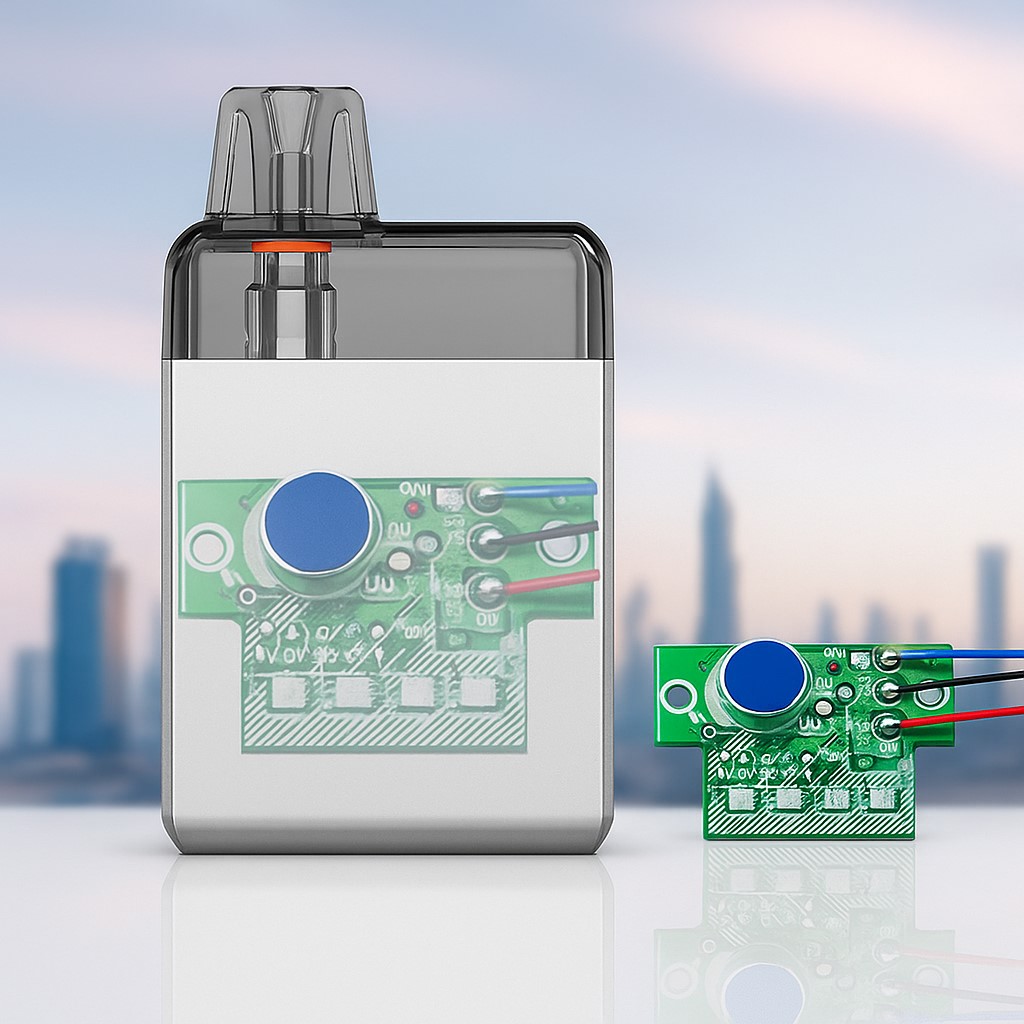

For a long time, China, leveraging its efficient production capacity and comprehensive supply chain, has become the global hub for e-cigarette manufacturing, handling massive orders from regions including Europe, the US, the Middle East, and Southeast Asia. Data shows that China accounts for over 90% of global e-cigarette production capacity. This “manufacturing powerhouse” status enabled Chinese manufacturers to rapidly accumulate extensive experience and substantial profits during the industry’s take-off phase.

However, the reality is clear: strong manufacturing capabilities do not automatically translate into dominance in the global market. As developed regions like Europe and the US continuously tighten e-cigarette regulations, raising compliance barriers, the traditional model reliant on “low-cost OEM, rapid delivery” is gradually losing its competitive edge.

We must recognize the new pattern of globalization: Manufacturing advantages are gradually diminishing; compliance and brand are the new passports to the global market.

1.1 Manufacturing Powerhouse ≠ Market Leader

Although China currently holds over 90% of global e-cigarette production capacity, its voice is remarkably weak in brand influence, policy formulation, technical standards, and the global end-value chain.

Regulatory bodies in major global markets are setting the rules of the game around product safety, youth protection, and sustainability. If China does not participate in shaping these rules, it faces the fate of passive acceptance and potential obsolescence.

1.2 The New Wave of “Globalization” is Compliance-Driven + Responsibility-Driven Globalization

In the past, industry competition focused on price, speed, and capacity. Now, the core of competition has shifted to compliance with target country laws, ESG reporting, traceability, and adherence to standards like PMTA (Premarket Tobacco Product Application), TPD (Tobacco Products Directive), MOPH (Ministry of Public Health requirements), etc. Mastery of the global regulatory language is key to succeeding in the market.

02 Globalization Enters a New Era of “Compliance + Responsibility”

Past globalization emphasized production costs and logistics efficiency. The new globalization is a deep contest of compliance and responsibility.

Policy-Driven Reshaping of Industry Rules

Major global markets are actively formulating and refining e-cigarette regulations to reshape industry rules. Examples include the US PMTA, which imposes strict requirements on product ingredients and safety, mandating approval for any product entering the US market; the revised EU TPD, which sets higher standards for product specifications and packaging labeling; and the UAE’s ESMA (Emirates Authority for Standardization and Metrology), which clarifies norms for e-cigarette sales and usage. These policies act as formidable barriers; only products fully compliant with local regulations gain market access.

Brand Trust Becomes the Core Competitiveness

Consumers and governments increasingly prioritize product safety, ingredient transparency, youth protection, and other social responsibilities. Brands must establish a “trustworthy” image. Only then can they gain consumer preference and government recognition, securing an advantageous position in the competitive landscape.

Rise of Green and Sustainable Trends

Environmental requirements and social responsibility are now global imperatives. Frequent bans on disposable products highlight that eco-design is a new competitive edge. Enterprises must prioritize the use of eco-friendly materials and resource circularity in their production processes to adapt.

03 The Core Advantages and Hidden Worries of Chinese Manufacturing

Facing this profound transformation, Chinese manufacturing retains significant strengths but also harbors vulnerabilities.

Core Advantages:

- Exceptionally Mature Supply Chain System: Integrated processes covering atomizer cores, e-liquid filling, assembly, and packaging enable highly efficient production.

- Agile R&D and Production Responsiveness: Capable of quickly adapting to rapidly changing regulations and market demands, swiftly adjusting R&D directions and production plans.

- Cost and Scale Advantages: In the short term, this advantage remains difficult for other regions to match, providing competitive space for enterprises.

Hidden Worries:

In the future, all three advantages above must be integrated with “compliance + trust + brand.” If enterprises remain confined to an “OEM + private label” mindset, neglecting the building of compliance capabilities and brand value, they risk marginalization. In the era of “compliance + responsibility” globalization, manufacturing prowess alone is insufficient.

04 The Transformation Path for Chinese E-cigarette Manufacturers Towards Global Markets

To establish and sustain long-term development in the global market, Chinese e-cigarette manufacturers need to undertake a series of measures, upgrading from manufacturing to “standard export + brand co-creation.”

Build a Global Compliance Hub

Enterprises should proactively study, participate in, and prepare for diverse national regulatory standards, achieving multi-dimensional adaptation in product design and submission documentation. Establishing an internal team of compliance experts, making it the primary growth driver, is crucial. This team must closely monitor policy changes globally, providing timely strategies to ensure products meet target market regulations.

Create an Export-Oriented Product System

Enterprises must not only manufacture products but also develop a complete product standard system. This includes safety testing, ingredient traceability, user responsibility mechanisms, etc., forming a replicable and implementable set of technical and service standards. Such a system enhances product quality, safety, and international competitiveness.

Participate in Brand Ecosystem Co-creation

Enterprises must move beyond simple ODM (Original Design Manufacturing) and embrace brand co-creation. Through cooperation, joint ventures, or co-management, they can build localized brand images, strengthening product trust in target markets. Collaboration requires a deep understanding of local culture and consumer needs to develop suitable products and brand strategies.

Construct a Cross-Border Trust Network

Establish expert advisory boards, government relations networks, and social responsibility alliances. Actively participate in industry governance and public welfare projects to enhance the international image of “Chinese products.” Collaboration with experts, governments, and society builds credibility and influence, fostering a favorable environment for product promotion and sales.

Conclusion

Chinese manufacturing holds an irreplaceable position in the global e-cigarette supply chain. However, winning the future global market hinges not on mere “low-cost manufacturing,” but on becoming a “standard-setter” and “brand value creator.”

This represents a profound shift from “production speed” to “compliance speed,” from “quantity advantage” to “quality and trust advantage.” For all Chinese e-cigarette OEM enterprises, this is both a crisis and an exceptional opportunity.

The next stage for Chinese manufacturing’s global expansion is not simply shipping goods, but exporting standards, building brands, and establishing trust. Enterprises that awaken timely and proactively transform will undoubtedly achieve remarkable success in the global marketplace.