Modern consumers increasingly seek healthier alternatives to traditional smoking. Among these alternatives, nicotine-free candy e-cigarettes have emerged as a growing trend, particularly favored by younger demographics and health-conscious users. While the flavors and marketing receive the most attention, the technological core of these devices lies in the Printed Circuit Board Assembly (PCBA). Let’s explore how PCB innovations shape the functionality, safety, and user experience of candy-flavored, nicotine-free vape devices.

1. Evolving User Demands Drive PCB Innovation

The shift toward nicotine-free candy e-cigarettes demands more than flavor innovation. As usage increases, so does the need for compact, efficient, and stable PCBs. These designs must support various key functions, including battery regulation, heating control, LED management, and child safety mechanisms. To meet these diverse needs, PCB manufacturers must embrace high-density, low-power, and multi-layered configurations.

En plus, these devices often target younger users, so design requirements include aesthetic LED features, haptic feedback, and responsive sensors. Consequently, manufacturers must continuously optimize form factor and function simultaneously.

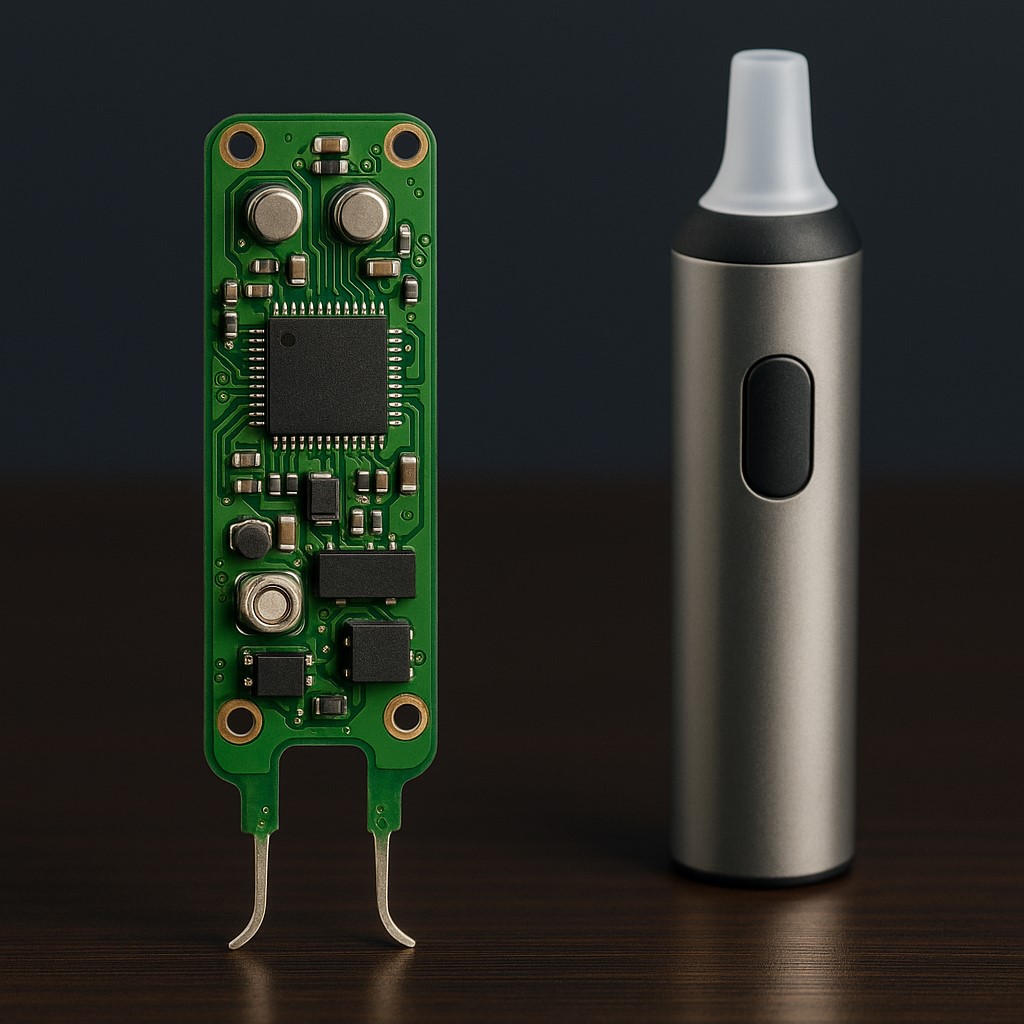

2. Core Components of PCBA in Candy E-Cigarettes

Though small in size, a nicotine-free candy e-cigarette typically integrates several critical components into its PCB:

- Microcontroller Unit (MCU): Orchestrates heating, LED, and safety features

- Battery Management ICs: Ensures controlled power delivery and safe charging

- Temperature Sensors: Regulate coil heat to prevent dry hits

- LED Drivers: Control lighting patterns for user feedback

- Airflow Sensors: Detect inhalation to activate the heating element

These elements must be compact and energy-efficient, as the battery size remains limited. Thus, PCB design becomes the key to balancing performance and power consumption.

3. Importance of Customization in Manufacturing

From a perspective, customization is essential. Every brand wants unique lighting patterns, draw sensitivity, or child-proof activation sequences. Par conséquent, PCBA suppliers must provide flexible layout services that enable clients to realize their differentiated product concepts.

De plus, many nicotine-free e-cigarettes are used as novelty or lifestyle accessories. Donc, PCBA solutions must be compatible with sleek, small form factor enclosures without compromising performance.

4. Thermal Management and Miniature Design

One technical challenge lies in thermal regulation. Even though nicotine-free devices may produce less vapor, precise temperature control remains vital. Uncontrolled heating can still lead to burnt flavors or short-circuits. Ainsi, PCBs must incorporate thermal sensors and auto-shutoff protocols to safeguard users.

En outre, miniaturization remains a persistent engineering challenge. Advanced substrate materials like flex-rigid PCBs and embedded passive components are increasingly applied to fit essential circuitry into compact dimensions while reducing electromagnetic interference.

5. Enhancing Safety Through Firmware and Hardware

Even without nicotine, safety is non-negotiable. Parents and regulators alike are concerned about underage usage. Accordingly, manufacturers often request PCBs with:

Draw-activation lock mechanisms

Session limits (e.g., time or puff count restrictions)

Overvoltage, surintensité, and short circuit protection

All these features are integrated via firmware and hardware collaboration. Suppliers must program and verify firmware logic directly onto the MCU while ensuring hardware safeguards remain active at all times.

6. Compliance and Quality Control

Nicotine-free does not mean regulation-free. In many regions, such devices must comply with standards for battery safety, electromagnetic compatibility (EMC), and material composition. For instance, RoHS and CE certification are mandatory in the EU market. Thus, PCB suppliers need extensive quality testing protocols, y compris:

- In-circuit testing (ICT)

- Burn-in stress testing

- Functional testing with vapor modules

These steps ensure each batch performs as expected under real-world conditions.

7. Integrating Wireless Features for the Future

As vape devices grow smarter, many brands begin to integrate wireless capabilities. Bluetooth modules allow app connectivity, enabling users to track puff counts, adjust settings, and update firmware. PCBs for these e-cigarettes must then include:

Low-energy Bluetooth chipsets

Secure memory blocks

Power-efficient antenna designs

While still optional for many clients, these features help future-proof devices and expand value-added offerings.

8. Sustainable Manufacturing Trends

Another growing demand is sustainability. Brands increasingly prefer lead-free soldering, recyclable PCB substrates, and efficient power regulation for reduced carbon footprint. By sourcing green PCB materials and optimizing circuit layouts for minimal waste, suppliers contribute to both regulatory compliance and brand values.

Conclusion: The PCB Behind Every Puff

In summary, the PCBA in nicotine-free candy e-cigarettes is far from simple. It combines sensor integration, power regulation, thermal control, and design customization— all within an ultra-compact form factor. For suppliers like Rimyi, responding to these needs with precision and scalability defines our value in the competitive market.

As the nicotine-free trend continues to grow, well-engineered PCB solutions will remain central to product safety, function, and brand differentiation. Whether through aesthetic lighting, user protection protocols, or wireless features, the technology behind the puff matters more than ever.