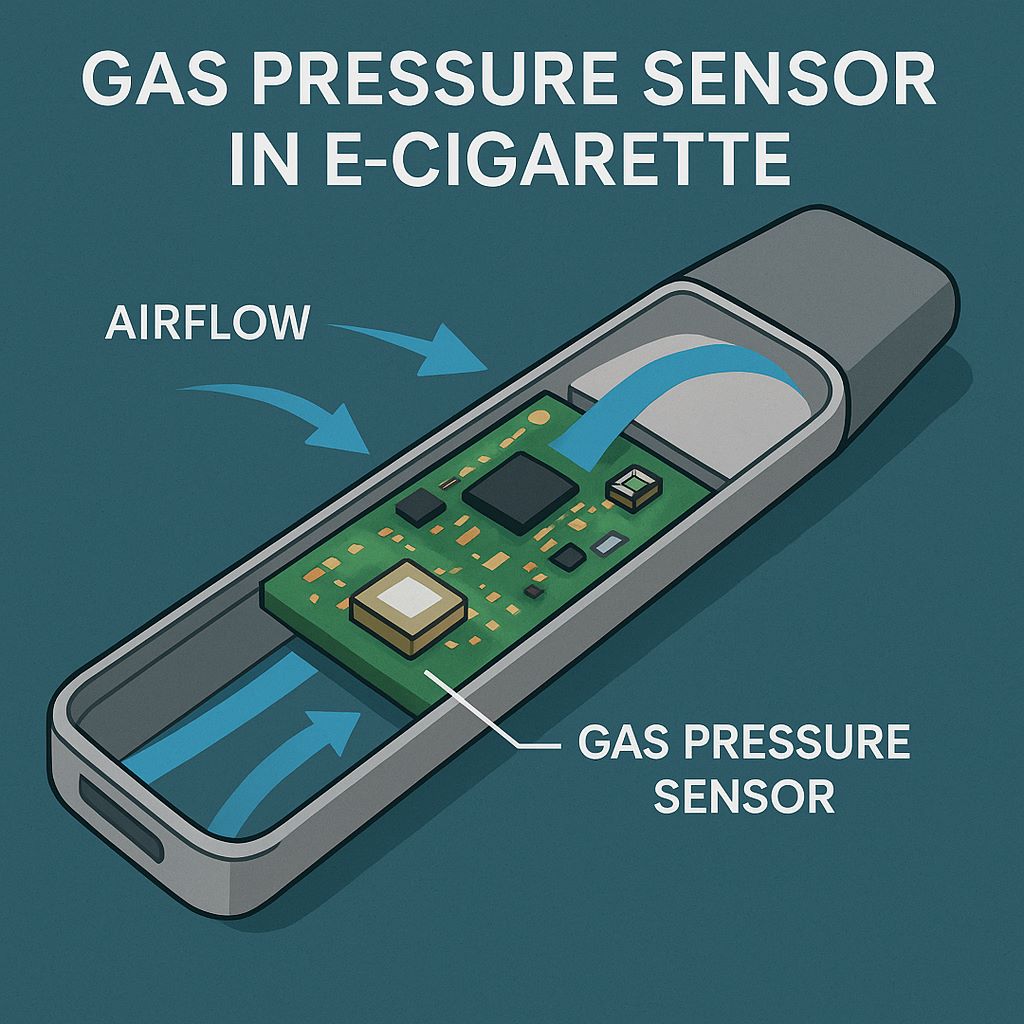

Inhalation detection is a core function of modern e-cigarettes, enabling a seamless and responsive user experience. Among various sensing methods, gas pressure sensors have become a popular choice for detecting airflow changes during vaping. They offer high precision, stable response, and the ability to integrate tightly with sensor-based e-cigarette control boards. However, to unlock their full potential, PCB designers must carefully balance sensitivity curves, signal acquisition quality, and anti-false trigger algorithms. In this article, we explore the circuit design considerations required for an optimal implementation, ensuring a stable and enjoyable vaping experience.

1. Why Use Gas Pressure Sensors in E-Cigarettes

Gas pressure sensors detect the slight negative pressure generated when a user inhales through the mouthpiece. Compared to mechanical switches or optical flow sensors, they provide:

-

Higher Sensitivity: Capable of detecting minimal air pressure changes, enhancing responsiveness.

-

Compact Integration: Easy to embed in small PCB layouts without affecting industrial design.

-

Extended Reliability: Fewer moving parts reduce wear and improve lifespan.

Furthermore, when integrated into sensor-based e-cigarette control boards, these sensors allow advanced firmware control, enabling intelligent vaping modes, draw-activated firing, and safety protections.

2. Understanding Sensitivity Curves in Pressure Sensors

The sensitivity curve describes the sensor’s electrical output as a function of applied pressure. It is critical to choose a curve profile matching the target inhalation force of the product.

-

Linear Response Curves: Provide predictable voltage changes, simplifying ADC calibration.

-

Non-linear Curves: Offer higher sensitivity at lower pressures but require algorithmic compensation.

In e-cigarette design, it’s essential to align the curve with the average draw strength of target consumers. For example, markets with a preference for tight draws require sensors tuned for rapid voltage changes at low negative pressures.

PCB designers must also consider temperature drift compensation, as e-cigarettes experience significant temperature fluctuations during use.

3. Signal Acquisition: Precision Matters

Accurate signal acquisition is the bridge between sensor data and reliable device operation. The core elements include:

-

ADC Selection: A 10–12 bit ADC is typically sufficient, but higher-resolution ADCs can reduce noise in high-sensitivity applications.

-

Sampling Rate: Must capture fast inhalation events without missing transient peaks.

-

Low-Pass Filtering: Eliminates high-frequency noise caused by environmental vibrations or electromagnetic interference.

A well-designed PCB layout will isolate the sensor’s analog traces from high-current switching components. Using shielded traces or ground guard rings can further improve signal integrity.

4. Anti-False Trigger Algorithms

False triggering can occur from external air movements, transportation vibrations, or rapid temperature changes. Effective anti-false trigger strategies include:

-

Threshold Hysteresis: Prevents rapid on-off switching by requiring the signal to exceed a defined margin before activation.

-

Time-Based Debounce: Ensures the inhalation signal persists for a minimum duration before firing the device.

-

Pattern Recognition: Uses microcontroller logic to differentiate between real inhalations and random airflow fluctuations.

When these algorithms are embedded in sensor-based e-cigarette control boards, they not only improve reliability but also help meet regulatory safety standards.

5. PCB Design Considerations for Sensor Integration

Integrating a gas pressure sensor into an e-cigarette PCB requires attention to both mechanical and electrical aspects.

-

Mechanical Placement: The sensor must have a direct airflow path without obstruction, yet be protected from e-liquid condensation.

-

Moisture Protection: Applying conformal coating or hydrophobic membranes prevents long-term degradation.

-

Power Management: Use low-power standby modes to conserve battery life while ensuring fast wake-up.

The PCB should also allow for firmware updates so that sensor performance can be tuned post-production, enabling adaptability to evolving user feedback.

6. Case Example: Optimizing for Different Markets

For example, a compact fruit-flavored vape stick targeting light puff users in Europe might use a sensor with a steep low-pressure sensitivity curve, paired with a 12-bit ADC and a tight debounce time. In contrast, a high-wattage box mod for Southeast Asia may require a broader curve, faster sampling, and adaptive threshold algorithms to handle powerful draws.

Conclusion

Gas pressure sensors have revolutionized inhalation detection in modern e-cigarettes, providing unmatched sensitivity and reliability when paired with well-designed sensor-based e-cigarette control boards. By understanding sensitivity curves, optimizing signal acquisition, and implementing robust anti-false trigger algorithms, designers can ensure a consistently smooth vaping experience.

RIMYI’s expertise in PCB design for vaping applications enables brands to integrate these sensors effectively, balancing engineering precision with user expectations. As market demands evolve, the ability to refine these systems quickly will distinguish leading products from the rest.