The Impact of Ceramic and Metal Heating Elements on Low-Temperature Tobacco Heating Modules and PCB Material Selection Guide

In recent years, the electronic cigarette industry has rapidly evolved. One key technology driving this growth is the low-temperature tobacco heating module. These modules require precise thermal management to ensure user safety, product efficiency, and optimal tobacco flavor delivery. The selection of the heating element and printed circuit board (PCB) materials plays a crucial role in achieving these goals.

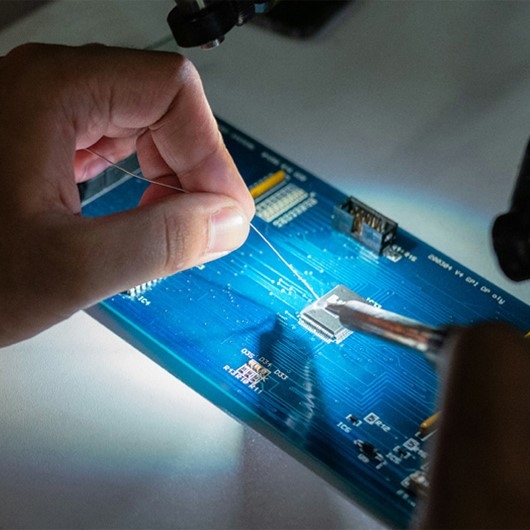

At RIMYI, we specialize in customized PCB solutions for electronic cigarettes. This article explores how ceramic heating elements and metal heater PCBs influence the performance of tobacco heating modules. It also provides a detailed guide on choosing the right PCB substrate based on the heating element used. Understanding these technical aspects will help manufacturers design safer, more efficient products.

Understanding Heating Elements in Tobacco Heating Modules

The heating element is the heart of a tobacco heating module. It transforms electrical energy into heat, warming tobacco sticks without burning them. This process reduces harmful combustion byproducts and enhances flavor. Two main heating element types dominate this sector: ceramic heating elements and metal heaters.

Ceramic Heating Elements

Ceramic heating elements consist of advanced ceramic materials. These ceramics possess excellent electrical insulation and thermal conductivity. Due to their unique properties, ceramic heaters can maintain stable temperatures and respond rapidly to control signals. Their advantages include:

-

High thermal stability, enabling precise temperature control.

-

Good electrical insulation reduces electrical leakage risks.

-

Uniform heat distribution improves tobacco heating consistency.

-

Long service life and resistance to thermal shock.

Однако, ceramic heaters generally require compatible PCB materials that support their thermal and mechanical characteristics.

Metal Heater PCBs

Metal heaters typically use resistive metal films or coils embedded directly on the PCB. Metals such as copper, nickel-chromium alloys, or stainless steel act as heating elements. Metal heater PCBs integrate the heating element and circuit substrate into a single unit. Key features include:

-

Fast heating response due to direct metal resistance heating.

-

Compact design allowing smaller module sizes.

-

Cost-effective production methods for high-volume manufacturing.

Metal heater PCBs demand substrates with excellent heat dissipation to avoid overheating and maintain product safety.

How Heating Element Type Influences PCB Material Selection

Selecting the correct PCB substrate depends heavily on the heating element. The substrate must accommodate thermal loads, provide electrical insulation, and maintain mechanical integrity. Below is a detailed comparison of PCB materials suitable for ceramic and metal heating elements.

PCB Materials for Ceramic Heating Elements

Ceramic heating elements require substrates that complement their thermal and electrical properties. Common PCB materials used include:

-

Aluminum-based metal-core PCBs (MCPCBs):

These PCBs feature an aluminum base with a dielectric layer and a copper circuit. Aluminum offers excellent heat dissipation, which prevents overheating. The dielectric layer must have high thermal conductivity to transfer heat efficiently from the ceramic element. -

Ceramic-based PCBs:

Pure ceramic substrates such as alumina or aluminum nitride provide exceptional thermal conductivity and insulation. Ceramic PCBs are highly reliable in high-temperature environments. They support the stable operation of ceramic heating elements but come at a higher cost. -

FR-4 with thermal vias:

Although FR-4 is the standard PCB substrate, its thermal conductivity is relatively low. For ceramic heaters, enhanced FR-4 boards with thermal vias and heat sinks can be used for moderate heat dissipation needs.

PCB Materials for Metal Heater PCBs

Metal heater PCBs face different thermal challenges, requiring substrates optimized for direct heating elements:

-

Metal Core PCBs (Aluminum or Copper):

These are the most common substrates for metal heater PCBs. Copper cores provide superior thermal conductivity but cost more than aluminum. Both allow fast heat dissipation, preventing localized hot spots. -

High thermal conductivity dielectric layers:

The dielectric layer between the metal core and copper circuit must have low thermal resistance. Materials like thermally conductive epoxy or ceramics are commonly used. -

Flexible substrates (polyimide-based):

For certain metal heater PCB designs requiring flexibility, polyimide films combined with metal layers provide good thermal performance and mechanical flexibility.

Thermal Conductivity and Its Role in PCB Performance

Thermal conductivity is a critical factor in PCB material choice. It determines how well heat transfers from the heating element to the environment. Insufficient thermal conductivity causes heat accumulation, risking device failure and user safety.

Ceramic heating elements need substrates with thermal conductivity ranging from 1.5 к 3.5 W/m·K or higher, depending on power density. Metal heater PCBs, especially those with embedded metal films, require even higher conductivity to avoid hot spots.

At RIMYI, we recommend thermal conductive substrates with optimized dielectric thicknesses. This balances electrical insulation and heat transfer. Более того, PCB surface finishes like HASL or ENIG influence thermal performance and solder joint reliability.

Electrical Insulation and Safety Considerations

Besides thermal aspects, electrical insulation is paramount. Ceramic heaters inherently provide electrical isolation. Однако, the PCB dielectric layer must support high breakdown voltage and prevent leakage currents.

Metal heater PCBs, integrating heating elements on conductive substrates, require careful dielectric design. The insulation layer must prevent short circuits and withstand thermal cycling stresses.

Safety certifications such as UL or IEC compliance demand rigorous testing of PCB materials and assemblies. Choosing materials meeting these standards ensures product reliability.

Mechanical Stability and Durability

Repeated heating cycles induce mechanical stress due to thermal expansion. PCB materials must withstand these stresses without delamination or cracking. Ceramic PCBs offer superior mechanical robustness but at a higher cost and brittleness.

Metal core PCBs with aluminum or copper bases offer good mechanical stability and cost-effectiveness. Proper design, such as optimized layer thickness and substrate bonding, enhances durability.

Customizing PCB Solutions with RIMYI

RIMYI provides tailor-made PCB solutions for electronic cigarettes, focusing on optimal heating module performance. Our engineers analyze heating element types and module requirements to recommend suitable PCB substrates.

We offer:

-

High-thermal-conductivity metal core PCBs customized by thickness and dielectric material.

-

Ceramic substrate PCBs with precision circuit patterning for advanced heating modules.

-

Flexible PCB options with embedded metal heaters for compact designs.

-

Material testing and thermal simulation services to ensure safety and efficiency.

Our deep industry expertise allows us to support manufacturers in delivering reliable and innovative tobacco heating modules.

Заключение

The choice between ceramic heating elements and metal heater PCBs significantly impacts the design of low-temperature tobacco heating modules. Each heating technology demands specific PCB materials with tailored thermal, electrical, and mechanical properties.

Ceramic heating elements benefit from substrates offering excellent insulation and thermal stability, such as ceramic PCBs or aluminum-based MCPCBs with high thermal conductivity dielectric layers. Metal heater PCBs require metal core substrates with efficient heat dissipation to manage direct resistive heating safely.

At RIMYI, we emphasize a comprehensive approach to PCB material selection. By aligning heating element characteristics with PCB substrate properties, manufacturers can ensure product safety, производительность, и долголетие.

Our customized PCB solutions optimize thermal management and electrical reliability for your e-cigarette products. Partner with RIMYI to leverage industry-leading expertise and deliver superior tobacco heating modules.