Selecting the best vape airflow sensor is crucial to optimizing product performance. Among the mainstream technologies, capacitive and piezoelectric sensors dominate. However, understanding vape airflow sensor technology differences helps ensure the right fit for specific vape designs. This article compares these two types in terms of response time, sensitivity, cost, and lifespan.

Response Time: Speed Matters

In vaping devices, fast response time ensures a smooth user experience. Capacitive sensors typically respond within milliseconds. Because they detect changes in dielectric properties, they react almost instantly when airflow begins. Meanwhile, piezoelectric sensors also offer quick responses but may slightly lag due to their mechanical structure. Therefore, if immediate vapor activation is essential, capacitive sensors often perform better.

Sensitivity: Detecting Subtle Airflow

When comparing sensor sensitivity, both technologies show strengths. Capacitive sensors can detect minimal airflow changes. This high sensitivity is ideal for low-draw vaping. On the other hand, piezoelectric sensors produce electric charges based on mechanical stress, allowing good airflow detection under moderate to strong puffs. Yet, for precise low-flow sensing, capacitive types often lead the way.

Cost Considerations

Cost is a critical factor in large-scale manufacturing. Capacitive airflow sensors are generally more affordable. Their simple structure and compatibility with standard electronics reduce production costs. Piezoelectric sensors, however, require special materials and complex designs. As a result, they are often more expensive. When cost-efficiency is a top concern, capacitive options are typically preferred.

Lifespan and Durability

Lifespan determines the product’s overall value. Capacitive sensors operate with no moving parts, ensuring long-term reliability. They are less prone to mechanical fatigue. Piezoelectric sensors involve physical deformation and may degrade over time. Although high-quality piezo materials extend lifespan, capacitive sensors still hold a slight edge in long-term use.

Final Thoughts: Application-Based Selection

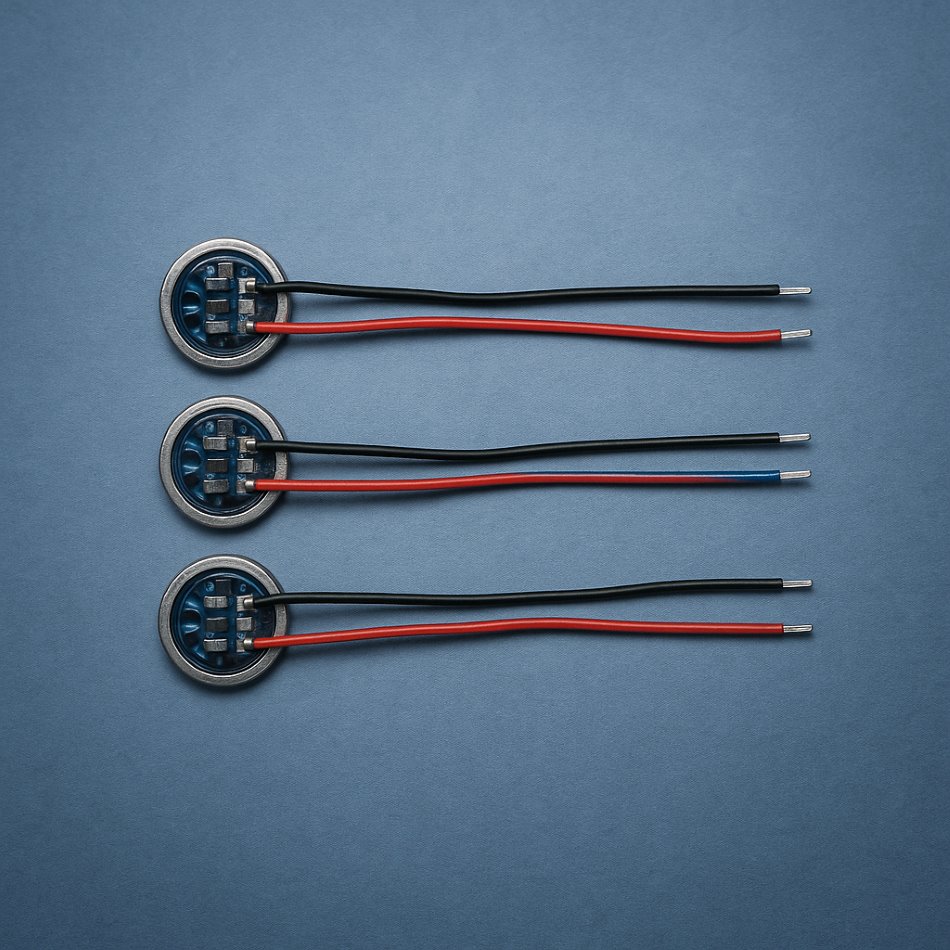

Both technologies serve well in specific vape scenarios. If your design requires high sensitivity, fast response, and lower cost, capacitive airflow sensors are ideal. However, if your product demands robust detection under higher pressure and cost is secondary, piezoelectric sensors offer reliability.

Why Choose RIMYI for Sensor Solutions?

Why Choose RIMYI for Sensor Solutions?

At RIMYI, we specialize in customized vape airflow sensors. Whether you require capacitive airflow sensors for compact e-cigarettes or piezoelectric solutions for premium models, we deliver high-quality, reliable components. Our engineering team ensures that every sensor meets your performance and regulatory needs.

結論

Choosing the right vape airflow sensor technology directly impacts product success. With capacitive sensors offering speed and cost benefits, and piezoelectric sensors excelling in mechanical applications, each has its place. Partner with RIMYI to ensure your devices meet evolving market demands with precision and performance.